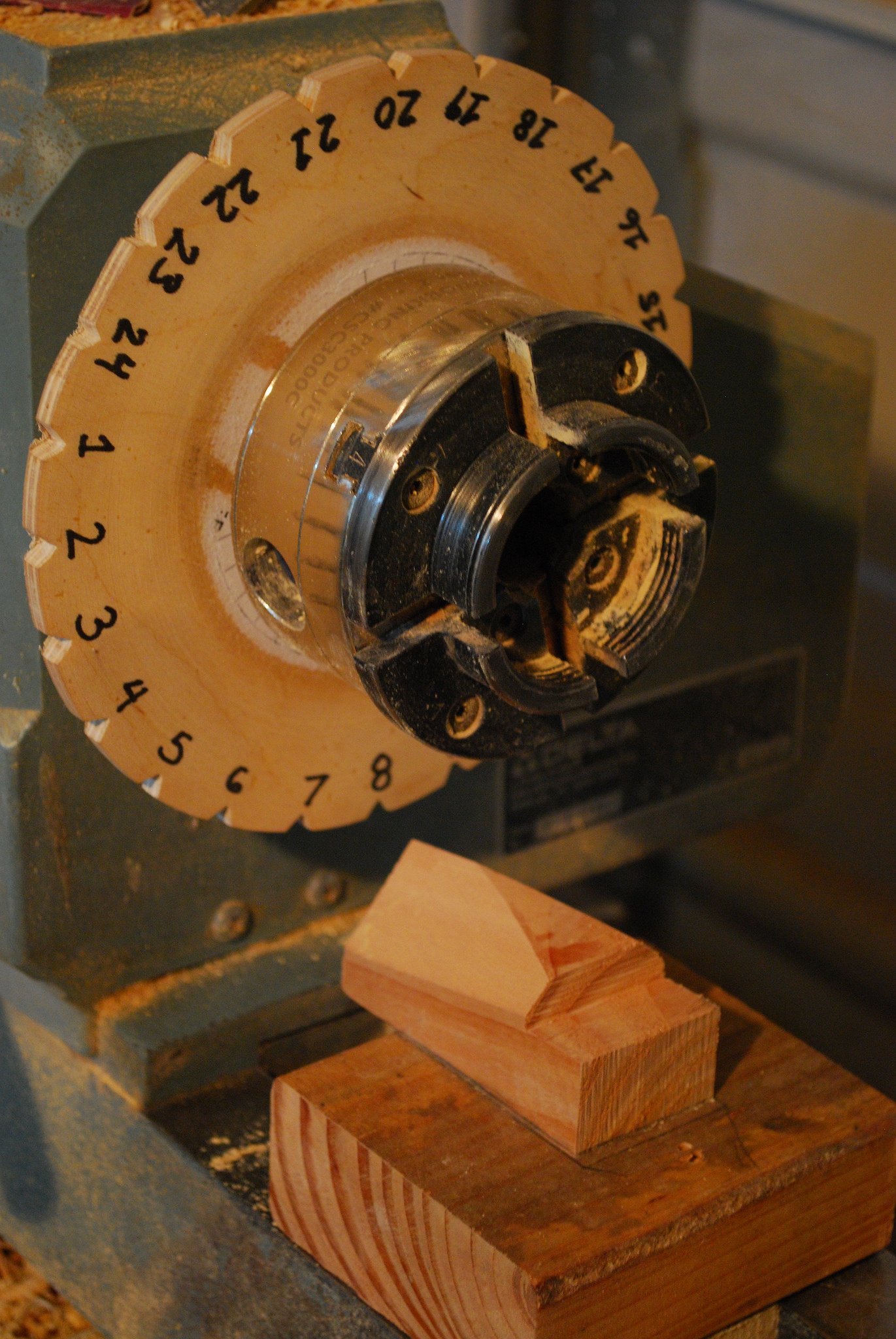

Indexing Plate

Occasionally a project calls for making holes / marks in regular intervals around a turned workpiece. For the markers on a clock, for instance. Or on a bowl for aesthetic appeal. These cases call for an indexing plate.

While some lathes have an indexing system built in, other lathes have to make do. David Reed Smith came up with an idea to make a plate that has been turned round and then small wedges cut out. It should be thin enough to fit on the threads behind the chuck, and the wedges deep enough for a locking pin to register in it.

I found this system to be very stable, and it’s easy to make plates in any necessary count.